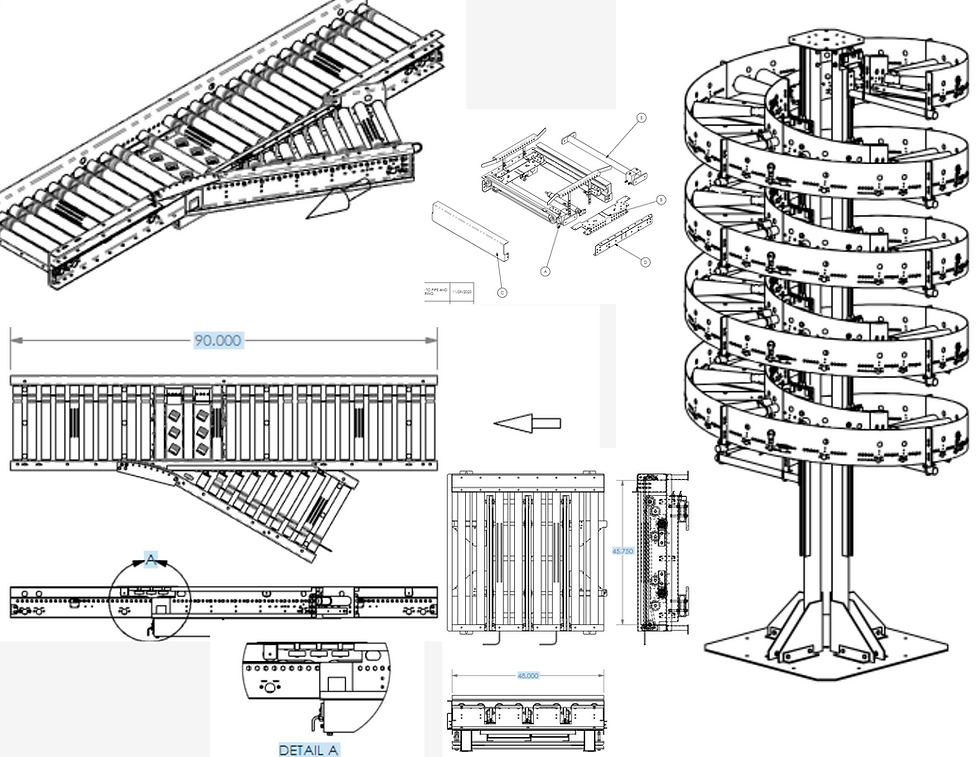

480VAC Conveyor Systems

A 480 VAC conveyor system is built for high-demand operations that move heavy loads over long distances. These systems run on three-phase alternating current, providing consistent power and torque for industrial facilities.

480 VAC conveyors are common in warehouses, manufacturing plants, and distribution centers where uptime and performance matter most.

Facility Functions designs, Inc., installs, and modernizes 480 VAC conveyor systems with a focus on safety, reliability, and efficiency - helping businesses keep production lines moving smoothly while identifying opportunities to reduce energy costs and simplify maintenance.

Key Takeaways

-

High Power and Torque: AC motors provide robust performance for heavy loads

-

Longer Conveyor Runs: Efficient for systems that need to transport high loads that span long distances (>100’)

-

Flexible Control: Can be paired with VFDs for speed adjustments through a PLC, or set to a constant speed

-

Durable and Proven: The standard conveyor drive method for decades

What is a 480VAC Conveyor System?

480VAC conveyor systems have long been the industrial standard for moving heavy materials across long distances. Powered by alternating current (AC) motors, these conveyors drive rollers, belts, or chains to transport products reliably through a facility. They can operate at a constant speed for simplicity or use variable frequency drives (VFDs) for precise speed control and energy optimization.

Built for high torque, durability, and continuous operation, 480VAC conveyor systems are the preferred choice in environments demanding rugged performance and long-duty cycles - such as manufacturing, bulk material handling, and heavy industrial applications.

Performance Highlights

-

Continuous-duty rated for industrial workloads

-

Configurable for high-torque or high-speed operation

-

Scalable to long conveyor runs with minimal power loss

-

Compatible with harsh and demanding environments

Optional Features

-

Variable Frequency Drives (VFDs) for precision speed control

-

Explosion-proof motors for hazardous environments

-

Custom belt materials for chemical or high-temperature applications

-

Safety guards and emergency stops integrated per OSHA/ANSI standards

-

Custom paint or stainless finishes for hygiene or corrosion resistance

Our 480VAC conveyor systems are engineered for reliability, endurance, and power in industrial environments. They remain the backbone for heavy-load, long-run, and high-duty-cycle applications where continuous operation and high torque matter more than precision or quiet operation.

When should you use a 480VAC conveyor system?

You should use a 480VAC conveyor system when:

-

Operations that require transporting heavy loads over long distances

-

The system operates 24/7 with high duty cycles

-

Conveyor lines run hundreds of feet or more

-

Centralized controls are required for synchronized operations

What are the main advantages of 480VAC conveyor systems?

-

High power and torque for heavy-duty loads

-

Suitable for very long runs

-

Reliable performance under continuous operation

-

Mature, proven technology used worldwide

What are the downsides of 480VAC conveyors?

-

Higher energy use compared to 24VDC MDR conveyors

-

Lack precise start/stop and indexing capabilities of 24VDC MDR systems

-

More complex maintenance that require specialized service and troubleshooting certifications

-

Louder operation and more vibration

-

Safety risks due to high voltage and torque

-

Complex installation with conduit, cabling, and electrical code requirements

-

Higher maintenance costs for motors, gearboxes, and belts due to number of parts required, ease of access, increased vibrations, continuous operations, etc

-

Drive configurations limit design flexibility for custom applications

How do 480VAC conveyor systems compare to MDR conveyors?

Below table compares the 24VDC conveyor system with the 480VAC conveyor system.

Industries Using 480VAC Conveyor Systems

Facility Functions provides end-to-end support for 480VAC conveyor systems and specialize in retrofitting to more modern and efficient systems.

Manufacturing and Heavy Industrial

480VAC conveyor systems are used to move large parts, assemblies, and pallets through production lines. Their high power output supports continuous operation in demanding environments such as automotive, metalworking, and equipment manufacturing.

Mining and Aggregates

In mining and aggregate facilities, 480VAC conveyors handle bulk materials like ore, gravel, and crushed stone. The systems are built to withstand harsh conditions, long runs, and heavy loads while maintaining consistent throughput.

Agriculture and Bulk Material Handling

These conveyors are used to transport grain, feed, fertilizer, and other bulk materials across large processing or storage areas. The 480VAC setup provides the power needed for long-distance conveying and stable performance in outdoor or dusty environments.

Food and Beverage Processing

Facilities use 480VAC conveyors to move packaged goods, containers, and ingredients through multiple production stages. Their power and control precision help maintain efficiency in continuous production while supporting hygienic, washdown-compatible equipment.

Recycling and Waste Management

Recycling plants and waste sorting facilities rely on 480VAC conveyors to move heavy, mixed materials such as plastics, metals, and paper. These systems deliver the torque and durability needed for continuous operation in high-impact, debris-filled conditions.

Considerations Before Choosing a 480VAC Conveyor System

Before choosing a 480VAC conveyor system, it’s important to evaluate your facility’s power infrastructure, load requirements, and operational goals. These systems are best suited for large-scale, continuous operations where high torque and long conveyor runs are necessary. You’ll also need to account for installation costs, electrical safety standards, and maintenance resources.

In many cases, a 24VDC conveyor system can achieve the same throughput with lower energy use, quieter operation, and simpler controls - making it a better fit for modern, flexible facilities.

Energy Consumption

-

AC Conveyor Systems consume 2–3x more energy than a comparable 24VDC MDR system handling the same throughput.

-

Energy usage increases with conveyor runtime and the weight of the load. Continuous-duty, heavy-load lines can quickly become expensive to operate.

-

24VDC MDR systems use low-voltage motors and distributed drives, meaning only active zones consume power. This makes them much more energy-efficient, especially in facilities with stop-and-start operation or intermittent use.

-

For heavy-duty, long-distance, continuous conveyors, AC systems remain the standard due to their torque and durability, but energy costs will be higher.

-

For medium-duty, modular, or intermittent conveyors, such as in e-commerce, order fulfillment, or automated sortation lines, 24VDC MDR systems are preferred because they minimize energy waste and reduce operating costs.

Safety

AC conveyors operate on high-voltage power, requiring strict adherence to electrical safety standards. Safety compliance is not a one-time step - it must be considered at every stage to ensure safe operation, reduce risk, and meet regulatory requirements.

To ensure safe operation:

-

Emergency stops, safety relays, and interlocks must be properly integrated into the control system.

-

Motors and drives should be enclosed or guarded to prevent contact.

-

Regular inspections of belts, rollers, and moving parts help prevent pinch-point injuries.

-

Training staff on lockout/tagout procedures is essential for maintenance.

-

Sensors and photoeyes should be configured to stop the conveyor immediately in case of product jams or unsafe conditions.

OSHA & NFPA 70E Compliance – Key Stages

-

Design Stage: Integrate safety requirements into conveyor layout, electrical systems, and guards.

-

Installation Stage: Ensure wiring, motor connections, safety devices, and guarding meet standards.

-

Pre-Operation / Implementation Stage: Test emergency stops, interlocks, sensors, and lockout/tagout procedures; document compliance.

-

Maintenance Stage: Regularly inspect guards, electrical panels, and safety systems; maintain lockout/tagout procedures and update safety documentation after modifications.

Controls Options

480VAC conveyors rely on:

-

Variable Frequency Drives (VFDs) for speed control and energy optimization.

-

Soft starters to protect motors from high inrush currents during startup.

-

Programmable Logic Controllers (PLCs) for automation, system logic, and integration with higher-level systems.

-

Safety relays for emergency stops and critical interlock functionality.

-

Sensors for product detection, accumulation, and line control.

Installation Considerations

Installing a 480VAC conveyor system requires licensed electricians and experienced technicians. Key installation steps include:

-

Running conduit and cabling – Deliver three-phase AC power to each motor through properly rated conduit, ensuring safety and code compliance.

-

Mounting drives and control panels – Install VFDs, soft starters, and motor control centers to regulate speed and protect equipment.

-

Connecting PLCs and safety systems – Wire the PLC to sensors, emergency stops, and other safety devices to manage line logic and automated operation.

-

Testing motor rotation and belt alignment – Verify correct motor rotation, torque, and synchronization. Align belts and rollers to prevent tracking issues.

-

Following OSHA and NFPA standards – Ensure compliance with conveyor and electrical safety regulations for both installation and long-term operation.

Maintenance Requirements

480VAC conveyor systems are built for continuous, heavy-duty operation, but proper maintenance is essential to ensure reliability, safety, and longevity.

Weekly Maintenance

-

Visual inspection of belts, rollers, and chains - check for wear, fraying, or misalignment; adjust or replace as needed.

-

Inspect and clean sensors and photoeyes - remove dust or debris.

-

Test emergency stops and safety devices - ensure relays and interlocks function properly.

-

Check motor and VFD operation - listen for unusual noise, vibration, or overheating.

-

Clean conveyor surfaces - remove debris to prevent damage or fire hazards.

Monthly Maintenance

-

Inspect bearings, shafts, and drive components - lubricate bearings, tighten hardware.

-

Check belt tension and alignment - adjust belts/rollers to prevent tracking issues.

-

Inspect electrical connections - tighten loose connections and check conduit for wear.

-

Review VFD and motor parameters - ensure settings match load and application.

Quarterly Maintenance

-

Inspect and lubricate gearboxes - check oil level (if applicable) and gear condition.

-

Inspect chain drives (if used) - check for wear, tension, and alignment; lubricate.

-

Perform load testing - run system at nominal loads to detect operational issues.

-

Review maintenance logs - identify recurring issues and schedule corrective actions.

Annual Maintenance

-

Comprehensive electrical inspection - verify wiring integrity, grounding, and insulation; inspect motor starters and VFDs.

-

Full conveyor alignment check - ensure rollers, belts, and pulleys are properly aligned and tensioned.

-

Replace worn components - belts, bearings, rollers, chains, or other high-wear parts.

-

Safety audit - verify compliance with OSHA, NFPA, and facility-specific safety standards.

-

Calibration of sensors and control systems - ensure PLC, photoeyes, and VFDs are functioning correctly.

How is control different in a 24VDC MDR conveyor system?

A 480VAC conveyor depends on a central PLC and large motor drives. In contrast, a 24VDC conveyor uses decentralized zone control.

-

Each conveyor zone has its own 24VDC motorized roller and small controller board.

-

Logic is built into each zone, so cartons accumulate, start, and stop automatically without a large PLC.

-

Wiring is simpler, with low-voltage cables instead of high-voltage conduit.

-

Expansions or layout changes are easier because new zones can be added without major rewiring.

In short:

-

480VAC = centralized control, high power, more complex wiring.

-

24VDC = decentralized control, modular zones, safer and more flexible.

This is why many facilities retrofit sections of AC conveyors with 24VDC MDR conveyors - they reduce wiring costs, increase safety, and simplify future expansions.

Choosing the Right Conveyor System

480VAC conveyor systems remain the workhorse of industrial material handling - built for power, endurance, and reliability. They excel in heavy-load, long-distance, or continuous-duty environments where high torque and uptime are critical.

However, as energy efficiency and flexibility become higher priorities, and MDR (Motor-Driven Roller) performance continues to exceed expectations, many facilities are transitioning portions or all of their operations to 24VDC MDR technology for lighter-duty, modular, or accumulation zones.

A well-designed system can successfully blend both: 480VAC conveyors where strength and transportation matters most, and 24VDC MDR where control and efficiency drive performance. This hybrid approach maximizes throughput, minimizes operating costs, and extends system life.

At Facility Functions, Inc., we specialize in helping operations select, integrate, and maintain conveyor systems tailored to their unique production needs. Whether you’re upgrading an existing line, converting to zone control, or designing a new installation from the ground up, our team provides end-to-end support-from design to commissioning.

Briefly introduce yourself and share something interesting with website visitors. Double click to edit the text.

WHAT PEOPLE SAY

Questions About Our 480VAC Conveyors

Help me choose: 480VAC vs. 24VDC MDR

-

Choose 480VAC conveyors for heavy loads, long-distance transport, and continuous operation.

-

Choose 24VDC MDR conveyors for energy efficiency, modularity, precise zone control, and quieter operation.

-

Many facilities benefit from a hybrid solution, using 480VAC where torque and durability matter and 24VDC MDR where efficiency and flexibility are priorities.

Still not sure which will work best for your specific application and product

Contact us now and a member of our sales team will contact you to discuss in more detail.

.png)

.png)